How 3D Printing is Reshaping Home Construction

The COVID-19 pandemic triggered a frenzy of home buying in Canada.

As we saw buyers chewed through the housing supply, the price of building materials like steel and lumber skyrocketed.

The world needs affordable housing like never before, but the good news is 3D printing technology is rising to the occasion.

3D printed homes are inexpensive, easy on the environment, and can be built in a matter of days.

Down in Mexico, Vantage West Realty funded the construction of a single-family home for only $10,000 USD through New Story Charity’s Architect Program.

This piece explores how 3D printing works in construction, and explains the advantages for builders and homeowners.

Afterwards, we’ll tour you around the most innovative 3D printed construction projects worldwide.

How 3D Printing Works in Home Construction

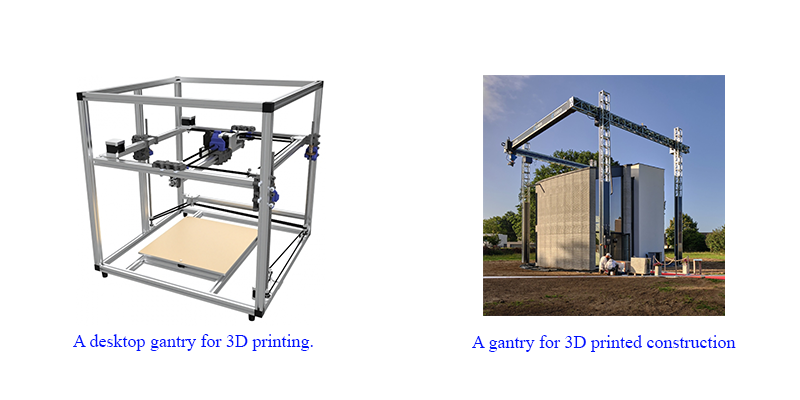

If you’ve ever watched a 3D printer work, 3D home printers work exactly the same on a larger scale. They build layer-by-layer by dripping a material like concrete, clay, or peat from a robotic arm attached to a gantry.

In 3D printing, a gantry is the metal structure that supports a 3d printer’s robotic arm.

These robotic arms each come equipped with extruders that deliver the building material into place. Extruders work similar to hot glue guns; they feed building material into position through a heated tube.

3D printers know where to place material based on instructions derived from architectural renderings (CAD files). CAD files are converted into 3D printing instructions using a slicer application.

Image Source: CNN.

The 3D Printing Process

The construction team prepares the site by excavating and grading the land to give the building a strong and level foundation.

Next the team installs the 3D printer into position, loads the slicer file and building material, then starts the 3D printing process.

Once the printer finishes building, the team takes down the machine.

Finally, they attach the roof (sometimes using a crane), then install doors, windows, heating, plumbing, and electrical systems.

Advantages of 3D Printing Homes

Speed

Robots just don’t tire out as fast as humans do.

We need people to set up, monitor, and disassemble 3D printers, but most of the work happens automatically - and at lightning speed.

We can build some 3D structures in under 24 hours.

The sheer speed of 3D printers makes them a perfect solution for rebuilding communities that have been hit by natural or economic disasters.

Image Source: Architectural Digest

Environmental Impact

When we use the right materials, 3D printing is really good for the environment.

This stunning 3D printed home in Italy was built in under 200 hours using locally sourced clay that eventually biodegrades back to the earth.

Some builders are now mixing peat with oil shale ash (an industrial waste product) to create a strong, economical, and environmentally-friendly building material that behaves a lot like concrete.

Cost

Because they’re fast and highly precise, 3D printing decreases homebuilding costs by as much as 30 to 40 percent.

As we see more 3D printing machines put to use, the overall cost of building should continue to decline.

However, it’s unclear if buyers and sellers will see lower home prices due to 3D printing. If demand stays hot and supply stays low over this next decade, land values may increase to make up the difference in value.

Image Source: Treehugger.com

Operating Efficiency

3D printers can produce wall designs that insulate against heat, cold, and humidity far better than conventionally-shaped building materials.

For example, the wasp’s nest-like structure shown above helps this building maintain a comfortable living environment year round using minimal energy inputs.

Novelty

Human hands would only struggle to produce the extraordinary home designs made possible by 3D printing.

From impossibly intricate sandcastles that wash away overnight to permanent concrete structures - the possibilities with 3D printing are limitless.

Let’s look at some of the most innovative 3D printing construction projects around the world.

3D Printed Construction Projects

New Story Charity Homes

ICON - Nacajuca, Mexico

In 2007, flooding destroyed many of the homes in Nacajuca, a city with 8,200 residents in the Mexican state of Tabasco. Ten years later, Mexico was rocked by a 7.1 magnitude earthquake.

In 2020, Vantage West Realty donated $10,000 USD to the New Story Charity, who has partnered with ICON Technology, Inc. to help rebuild Nacajuca with 3D printed homes.

The new home will go to a family who was previously living in a makeshift dwelling while earning less than $80 per month.

“Real estate was one of the most resilient sectors of the local economy in 2020, and we want to give back.” -AJ Hazzi, Vantage West Realty

Image Source: The Spaces

The Office of the Future

Killa Design - Dubai, United Arab Emirates

Finished in 2016, The Office of the Future was the first 3D printed building in history. The project saved 50% by using 3D printers loaded with concrete.

Image Source: Dezeen.com

A 3D Printed Community

ICON - Mexico

This community housing project designed by Yves Béhar aims to build 50 homes for impoverished Latin Americans.

Watch this animated video to see how ICON plans to build this community housing project, and what it will look like when it’s finished.

Image Source: 3Dnatives

Dubai Municipal Government Buildings

Apis Cor - Dubai, United Arab Emirates

The largest 3D printed structure today is this 2-story office in Dubai. It only took 3 weeks for the Russian firm Apis Cor to complete the project using locally sourced materials and prefabricated floor panels.

Image Source: 3DWasp

TECLA

WASP - Italy

TECLA (named after “technology” and “clay”) is one of the most innovative 3D printed homes yet. This eco housing project features a dome shaped roof, rounded door and window frames, and skylights in every room.

The clay walls are designed to control humidity and temperature using minimal energy inputs. TECLA is opening to visitors to the Italian commune of Massa Lombarda in Spring 2021.

Here are some more 3D home builders worth checking out:

Wrapping Up

In the not too distant future, we’re going to see 3D printing completely reshape the construction industry.

As the cost of living rapidly increases around the world, we hope that 3D construction projects like New Story Charity will lift millions of people out of poverty.

Looking beyond our blue planet, there’s a very good chance we’ll see autonomous 3D printers build the first human structures on the Moon or Mars sometime over the next 10 to 15 years.